EYE-WATERINGLY GOOD MUSTARD SINCE 1814

HOW WE GET THAT FAMOUS COLMAN'S KICK

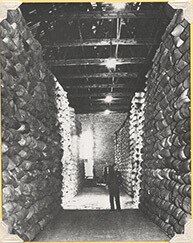

We perfected our English mustard long ago, so the process hasn’t changed much over the years. Unlike most mustard manufacturers, we sieve our seeds up to 9 times to remove any trace of impurities.That’s what gives it that famous full-on flavour.

The seed dryer building, built in 1890, still uses original wooden sieving equipment from the 1950s, too. Because if it ain’t broke, don’t fix it.

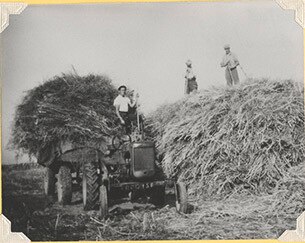

HELLO THERE, NEIGHBOUR

We want to support our local farmers, so all our white mustard, mint and apples are sourced in the UK. We’re working to increase the amount of locally sourced brown mustard we use, too, and all our seeds are milled on site in Norfolk.

KEEPING IT IN THE FAMILY

We’re proud of our Norfolk roots and our place in the community. We still source our mustard from many of the same farms we’ve always worked with, and in some cases, the same families. Some of our current farmers are 5th generation Colman’s mustard seed growers. Sunday lunch round ours is pretty serious business.

FROM FARM TO FORK

From Norfolk's mint fields to your family table.